Frequently asked questions

Company News

- Aluminum veneer customization, create your personalized space

- Fluorocarbon baked paint aluminum veneer: a new favorite in the aluminum industry, enjoying both quality and aesthetics

- Curtain wall aluminum veneer: a fashionable outerwear for modern architecture

- Painted aluminum veneer, perfect fusion of fashion and durability

- Fluorocarbon aluminum veneer: the fashion darling of the aluminum industry

Industry dynamics

- How to choose suitable stone patterned curtain wall aluminum veneer material

- Analysis of the advantages of stone patterned aluminum honeycomb panel in furniture design

- Aluminum veneer: improving the environmental performance of buildings

- Aluminum veneer provides a variety of shapes and colors for buildings to choose from

- Aluminum veneer curtain wall: the magnificent coat of modern architecture

Frequently asked questions

- Can the insulation function of aluminum veneer reduce indoor noise?

- What are the sustainability indicators of aluminum veneer in building exterior design?

- Is aluminum veneer prone to deformation?

- Can aluminum veneer be used for building facade design?

- How to evaluate the impact of aluminum veneer's removability on the appearance of buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Has the production process of aluminum veneer reduced water resource consumption?

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: February 22, 2025 11:18:10

- Click:0

Aluminum veneerHas the production process reduced water resource consumption?

With the continuous improvement of environmental awareness, people are paying more and more attention to the environmental performance of building materials. Aluminum veneer, as a new type of building material, has attracted much attention for its environmental performance. Among them, whether the production process of aluminum veneer reduces water resource consumption is also an important issue of concern. This article will explore whether the production process of aluminum veneer reduces water resource consumption from four aspects.

1、 Improvement of production process

In the traditional production process of aluminum veneer, a large amount of water is used for cleaning and cooling. The modern aluminum veneer production line adopts a closed production process, which can effectively reduce the amount of water used. For example, in the coating process of aluminum veneer, modern production lines adopt electrostatic spraying technology, which can evenly spray paint on the aluminum plate, reducing paint waste and saving a lot of water resources.

In addition, modern aluminum veneer production lines also adopt the technology of recycling water. During the cleaning and cooling process of aluminum plates, the used water will be recycled and reused after treatment. In this way, not only can water usage be reduced, but the impact of wastewater discharge on the environment can also be minimized.

2、 Optimization of materials

The selection of materials in the production process of aluminum veneer also has a significant impact on water resource consumption. In traditional aluminum veneer production processes, thicker aluminum plates are often used for processing, which requires more water for cooling and lubrication during the processing. Modern aluminum veneer production lines use lightweight aluminum plate materials, such as 0.5mm or 0.6mm thick aluminum plates, which can reduce the consumption of water resources during processing.

In addition, modern aluminum veneer production lines also adopt efficient coating technology. For example, using fluorocarbon coatings can give aluminum veneer surfaces good weather resistance and corrosion resistance, thereby extending the service life of aluminum veneer and reducing resource waste.

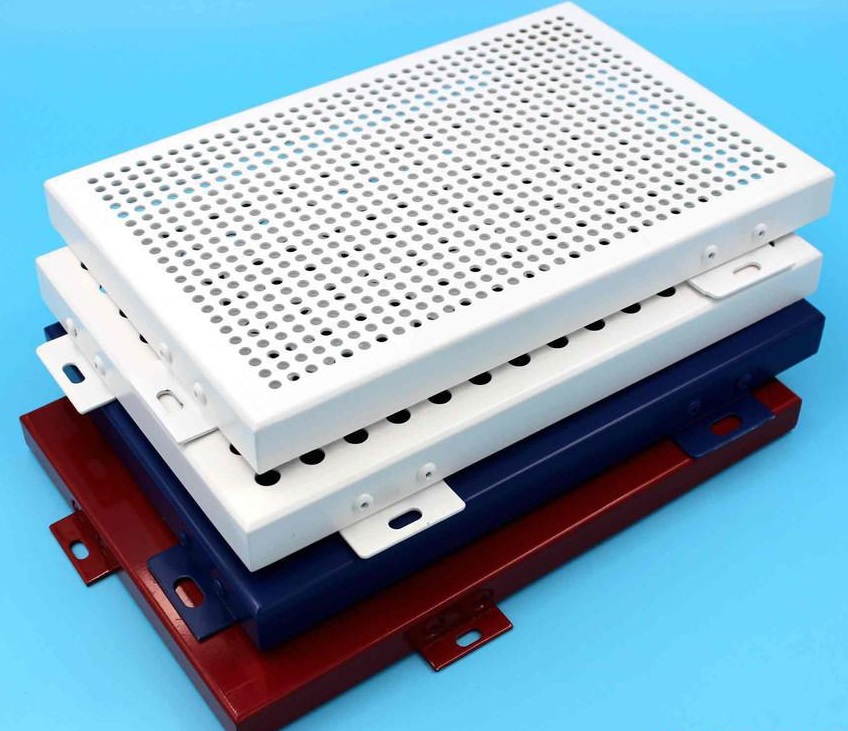

3、 Measures to save water

In the production process of aluminum veneer, in addition to improving production technology and material selection, some water-saving measures can also be taken. For example, in the cleaning and cooling process of aluminum plates, the technology of recycling water can be used to treat and reuse the used water. In addition, an efficient sprinkler system can be used to refine the amount of water used, thereby reducing the waste of water resources.

4、 Optimization of production environment

The production environment of aluminum veneer also has a significant impact on the consumption of water resources. Modern aluminum veneer production lines usually construct enclosed production workshops. By optimizing the air flow in the production workshop, the evaporation of water can be reduced, thereby reducing the consumption of water resources. In addition, efficient wastewater treatment systems can be used to reuse treated wastewater, thereby reducing the waste of water resources.

Summary:

In summary, modern aluminum veneer production lines have adopted various measures to save water during the production process, effectively reducing the consumption of water resources. These measures include improving production processes, optimizing materials, conserving water, and optimizing the production environment. With the continuous improvement of environmental awareness, aluminum veneer production enterprises will pay more attention to the issue of water conservation, further promoting the development of the aluminum veneer industry towards a more environmentally friendly and sustainable direction.

Customer service QQ

Customer service QQ