Industry information

Company News

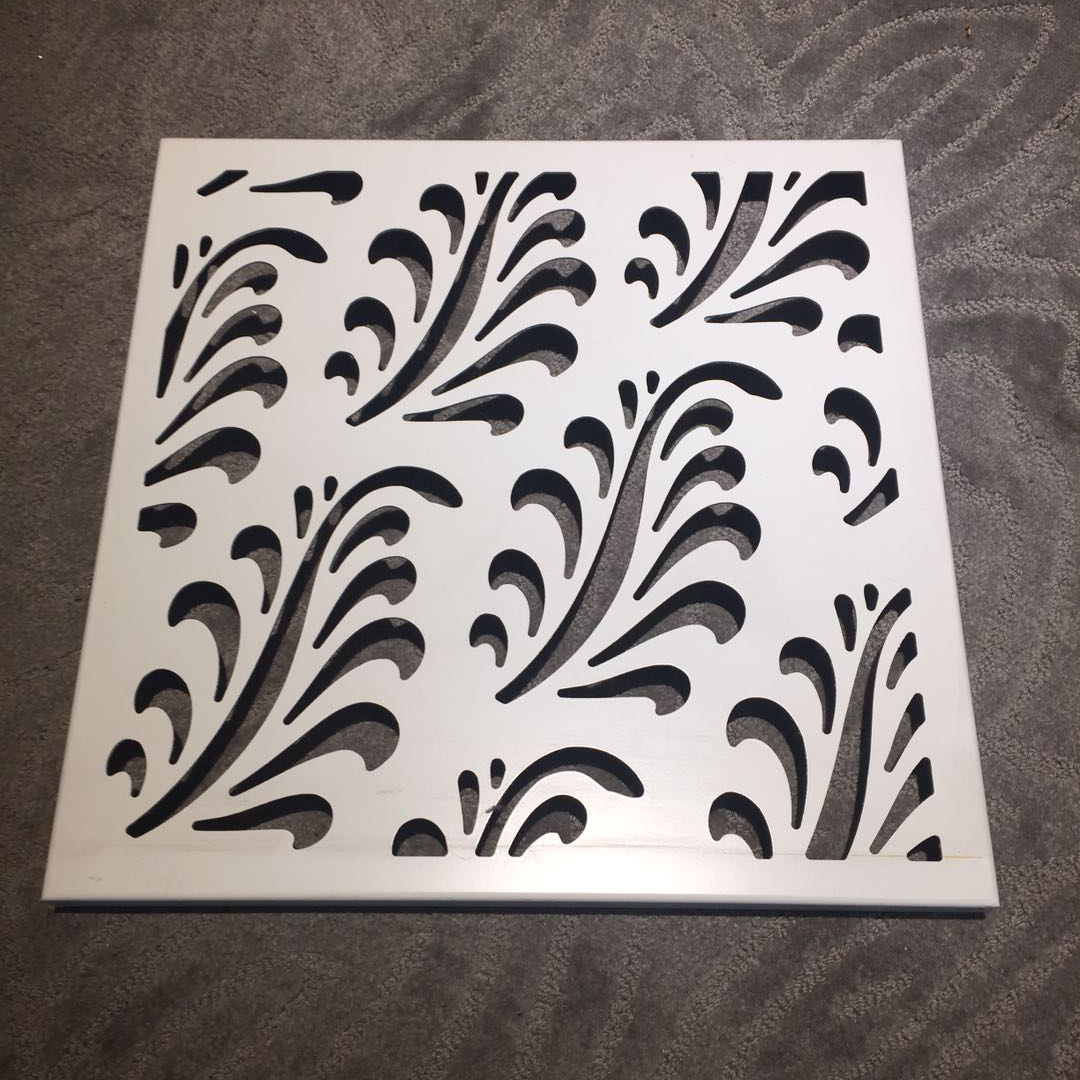

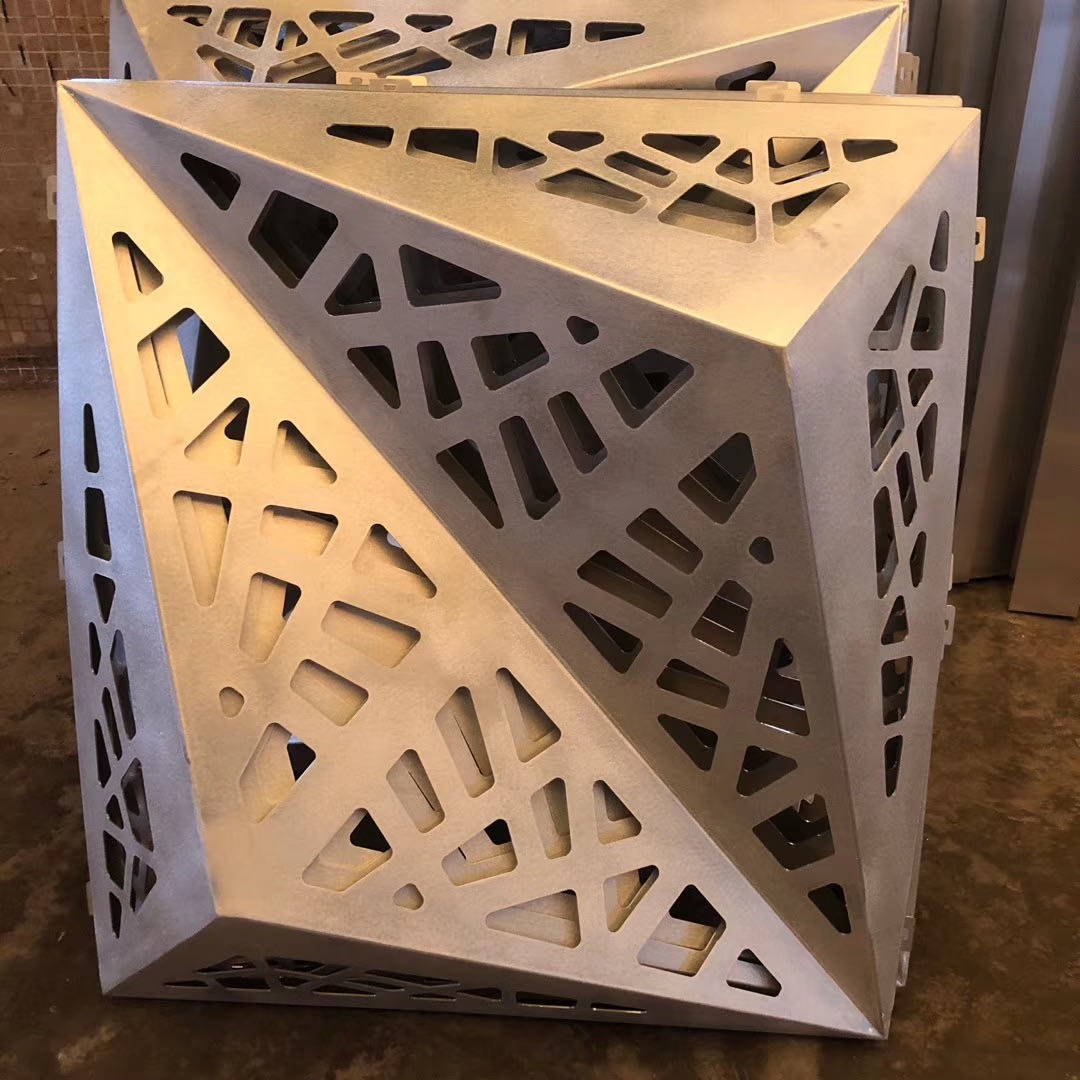

- Aluminum veneer customization, creating personalized spatial aesthetics

- Fluorocarbon baked paint aluminum veneer: the new favorite of aluminum materials and the chameleon of the construction industry

- Fluorocarbon aluminum veneer: the fashionable "coat" of future architecture

- Fluorocarbon aluminum veneer: a fashionable "light luxury" element in the construction industry

- Painted aluminum veneer: the fashionable choice for modern architecture?

Industry dynamics

- Fluorocarbon aluminum veneer: material innovation, new trend in construction

- Aluminum veneer has strong weather resistance and is not afraid of wind and rain

- Aluminum veneer curtain wall, a new chapter in the beauty of architecture

- Fluorocarbon baked paint aluminum veneer: a new choice for quality living and a rising star in the aluminum industry

- Aluminum veneer: a fashion revolution in lightweight building materials

Frequently asked questions

- Is aluminum veneer prone to deformation?

- Can aluminum veneer be customized?

- What are the sustainability indicators of aluminum veneer in building exterior design?

- How to evaluate the impact of aluminum veneer's removability on the appearance of buildings?

- What is the thermal conductivity of aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Aluminum veneer installation cost and budget reference

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: 2022-03-01 09:25:16

- Click:0

Aluminum veneerIt is a material widely used in fields such as construction and decoration, and its advantages of lightweight, high strength, and corrosion resistance have received widespread attention. When choosing aluminum veneer, in addition to considering its quality and performance, installation costs and budget also need to be taken into account. This article will provide a reference analysis on the installation cost and budget of aluminum veneer.

1. Cost composition of aluminum veneer installation

The installation cost of aluminum veneer mainly includes the following aspects:

(1) Labor cost: including the labor cost required for the measurement, cutting, bending, welding, installation and other processes of aluminum veneer.

(2) Material cost: including the material cost of the aluminum veneer itself and the cost of auxiliary materials such as screws, rivets, glue, etc.

(3) Equipment rental fee: If professional equipment is required for the processing and installation of aluminum veneer, corresponding equipment rental fees need to be paid.

(4) Transportation cost: If aluminum veneer needs to be transported from the manufacturer to the construction site, corresponding transportation costs need to be paid.

1. Budget reference

The installation budget for aluminum veneer needs to be determined based on specific circumstances, generally taking into account the following factors:

(1) The quantity and specifications of aluminum veneer: The labor and material costs required for different quantities and specifications of aluminum veneer will also vary.

(2) Construction difficulty and duration: The construction difficulty and duration will also affect the installation budget of aluminum veneer.

(3) Geographical location and market conditions: The price of aluminum veneer may vary in different regions and markets.

Generally speaking, the installation budget for aluminum veneer needs to be above 500 yuan/square meter, and the specific budget needs to be adjusted according to the actual situation.

1. Precautions

When budgeting for the installation of aluminum veneer, the following points should be noted:

(1) We should fully consider various problems that may be encountered during the construction process to avoid additional costs.

(2) Choose reputable manufacturers and suppliers to ensure reliable quality of the purchased aluminum veneer.

(3) Reasonably plan the construction schedule to avoid quality issues and additional costs caused by tight schedules.

Customer service QQ

Customer service QQ