Industry information

Company News

- Create an exclusive style and customize aluminum veneers to make the building more charming

- Fluorocarbon aluminum veneer: the fashionable "coat" of future architecture

- Aluminum veneer: the shining pearl of modern architecture

- Painted aluminum veneer: the "beauty responsibility" of the aluminum industry

- 2. Customized aluminum veneer, a stunning new choice for home decor. 3 Aluminum veneer customization, open

Industry dynamics

- How to choose suitable aluminum veneer materials

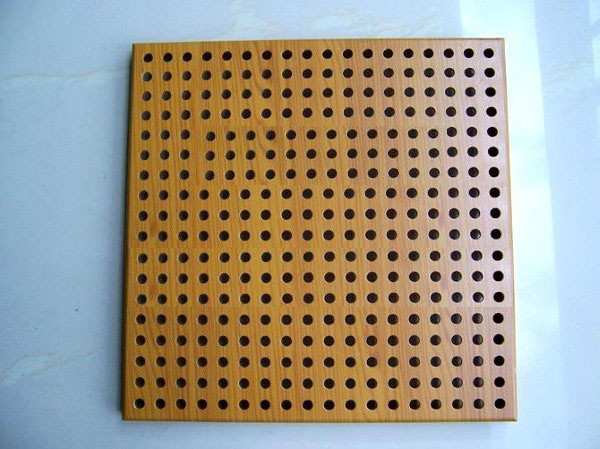

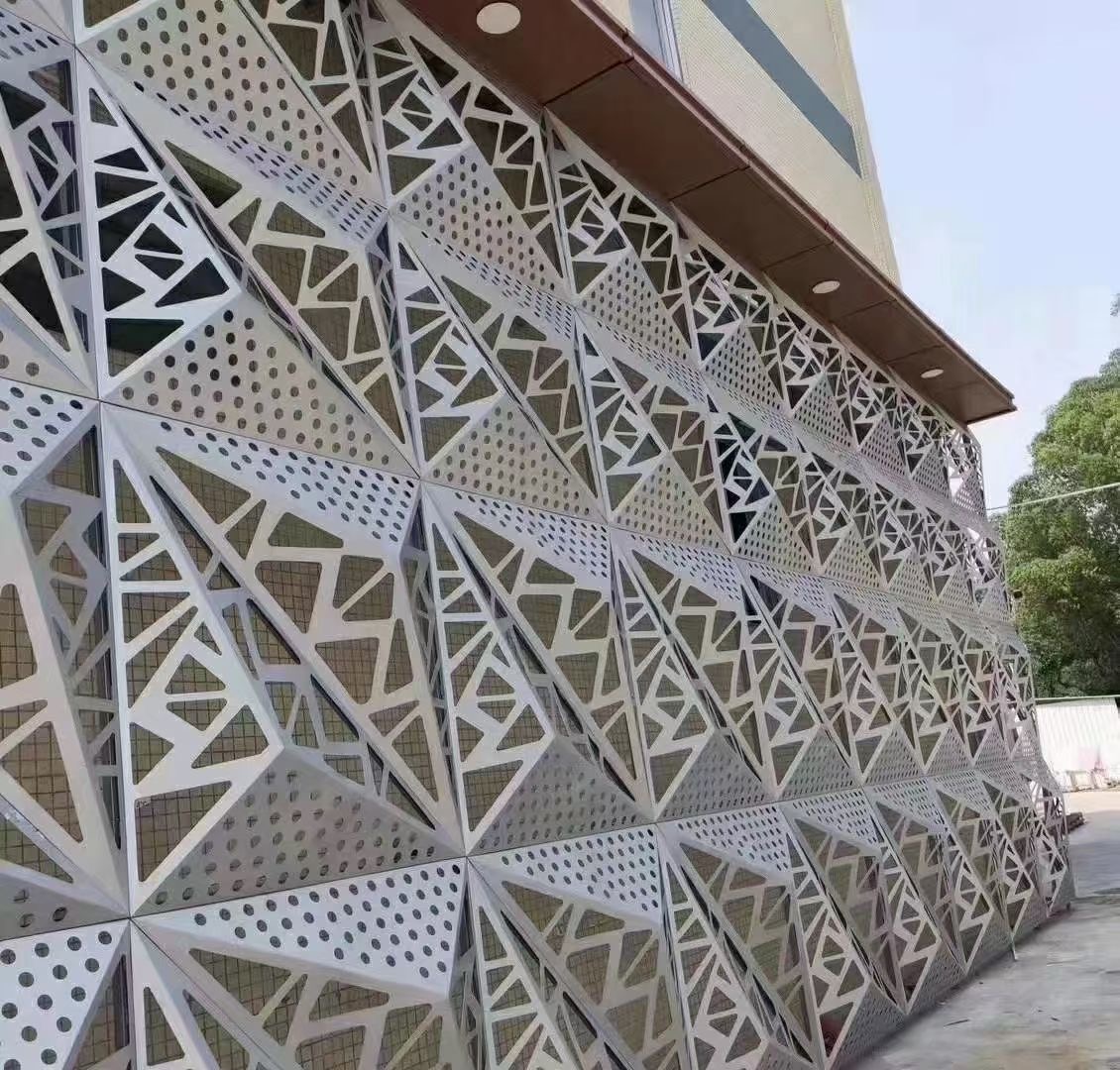

- Appreciate the charm of perforated aluminum veneer in the field of architecture

- Aluminum veneer curtain wall, the new darling of architectural aesthetics

- Fluorocarbon baked paint aluminum veneer: the "fashionista" in the aluminum industry

- Fluorocarbon aluminum veneer, the new darling of the construction industry, combines appearance and strength!

Frequently asked questions

- What is the thermal conductivity of aluminum veneer?

- What are the advantages and disadvantages of aluminum veneer compared to plastic exterior walls?

- Can the insulation function of aluminum veneer reduce indoor noise?

- How many color and texture options are available for aluminum veneer?

- Is aluminum veneer prone to deformation?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Customized installation process and technology for aluminum veneer

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: March 11, 2025 09:33:03

- Click:0

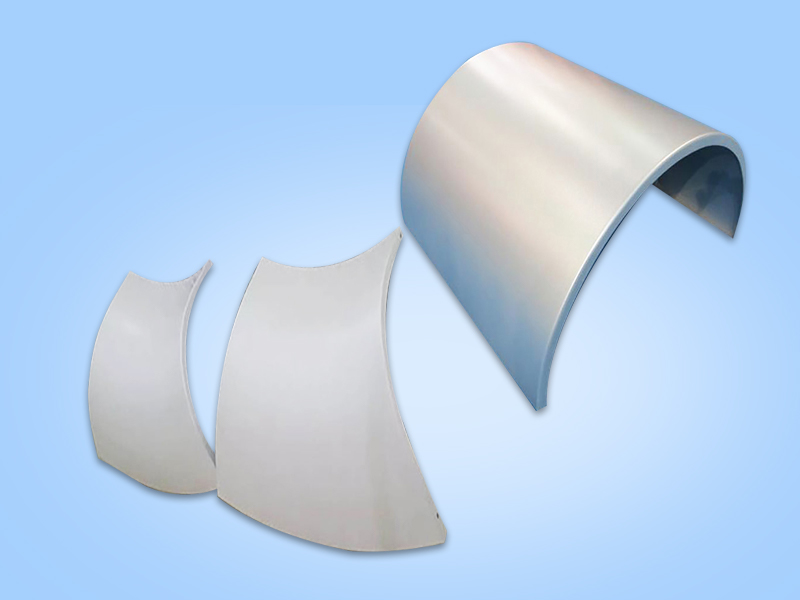

Aluminum veneerCustomization, as a new type of building decoration material, its installation process and technology are also important factors affecting the quality and aesthetics of products. Below, we will provide a detailed introduction for everyoneCustomized aluminum veneerThe content of installation process and technology.

1、 Preparation work before installation

1. Material inspection: Before customizing the installation of aluminum veneer, a comprehensive inspection and evaluation of the selected materials is required to ensure that their quality meets the requirements and that they are not damaged or defective.

2. Develop construction plan: Based on the customized design drawings and specifications of aluminum veneer, develop detailed construction plans and safety measures to ensure the safety and controllability of the construction process.

3. Prepare tools and equipment: Prepare the necessary tools and equipment according to the requirements of the construction plan, and conduct a comprehensive inspection and maintenance of these tools and equipment to ensure their normal operation.

2、 Installation process

1. Keel installation: Keel is the foundation for customized installation of aluminum veneer, and needs to be measured and arranged according to the requirements of the design drawings. The installation of the keel should be firm and reliable, and should be perpendicular to the wall to ensure the flatness and stability of the aluminum veneer.

2. Aluminum veneer installation: The installation of aluminum veneer should be carried out according to the requirements of the design drawings. First, place the aluminum veneer on the keel, and then fix it to the keel with self tapping screws or glue. During the installation process, it is necessary to pay attention to the direction and position of the aluminum veneer to ensure that it meets the design requirements.

3. Joint treatment: Joint treatment is required between aluminum veneers to prevent rainwater from seeping in and affecting the aesthetics. Joint treatment can be filled and fixed using materials such as sealant or silicone sealant.

3、 Installation Technology

1. Measurement accuracy: Before customizing the installation of aluminum veneer, a comprehensive measurement and evaluation of the wall dimensions is required to ensure that the selected materials and keels meet the design requirements. The measurement accuracy has a significant impact on the flatness and aesthetics of aluminum veneer.

2. Operation skills: During the installation process of aluminum veneer, attention should be paid to operation skills and methods to ensure installation quality and efficiency. For example, when using self tapping screws, attention should be paid to the accuracy of the force and direction to ensure that the aluminum veneer can be firmly fixed on the keel.

3. Safety measures: During the installation process of customized aluminum veneer, attention should be paid to safety measures to avoid accidents. For example, when using electric tools such as drills, attention should be paid to the stability and safety of the power supply to prevent accidents such as electric shock.

The installation process and technology of customized aluminum veneer are very important. In the actual operation process, it is necessary to strengthen the management and control of the installation performance of materials and products, actively respond to national policies and industry standards, and promote the healthy development of the aluminum veneer customization industry. We also need to pay attention to future development trends and issues such as environmental protection and energy conservation, constantly innovate and improve products and services, and meet customer needs and social expectations.

Customer service QQ

Customer service QQ