Industry information

Company News

- Customized aluminum veneer, a new trend in personalized space!

- Aluminum veneer customization, create your personalized space

- Aluminum veneer customization, creating the art of personalized space

- Fluorocarbon aluminum veneer: the new darling of architectural aesthetics

- 2. Customized aluminum veneer, the unique style of home, you deserve to have it! 3. Aluminum veneer customization

Industry dynamics

- Aluminum veneer customization, creating exclusive space aesthetics

- Fluorocarbon baked paint aluminum veneer: the "fashionista" in the aluminum industry

- Aluminum veneer curtain wall, the golden element of new fashion in architecture?

- High quality brushed carved aluminum veneer process

- Aluminum veneer has strong weather resistance and is not afraid of wind and rain

Frequently asked questions

- What are the advantages and disadvantages of aluminum veneer compared to plastic exterior walls?

- What are the sustainability indicators of aluminum veneer in building exterior design?

- Is aluminum veneer prone to deformation?

- What is the thermal conductivity of aluminum veneer?

- Can aluminum veneer be customized?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Analysis of Wind Load Resistance Performance of Aluminum Veneer

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: March 16, 2025 11:54:20

- Click:0

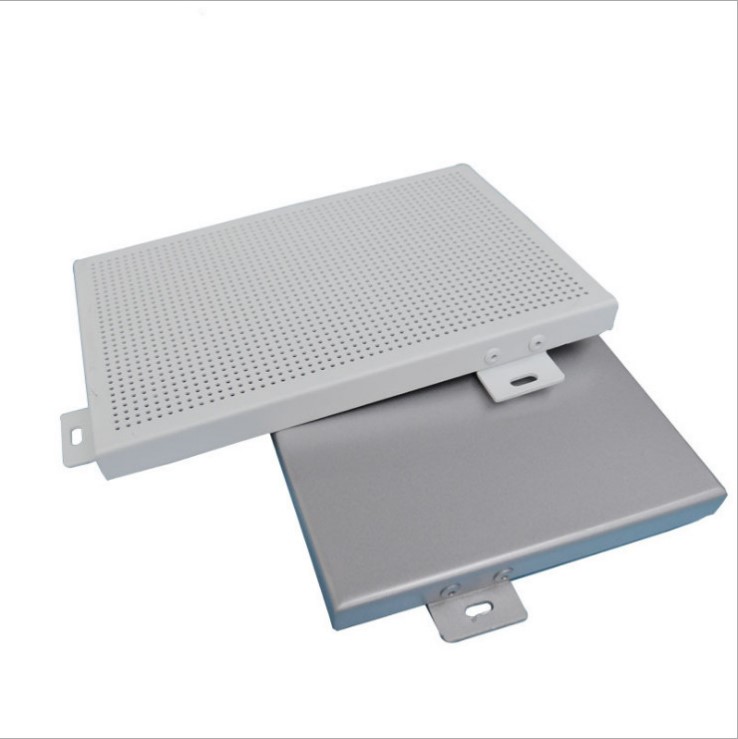

Aluminum veneerIt is a material widely used in fields such as construction and decoration, and its advantages of lightweight, high strength, and corrosion resistance make it an ideal choice. The wind resistance performance of aluminum veneer is also very important in strong wind environments. This article will analyze and explore the wind pressure resistance performance of aluminum veneer.

1. Wind pressure resistance performance indicators of aluminum veneer

The wind resistance performance of aluminum veneer is mainly measured by its strength and stiffness. Strength refers to the ability of a material to resist external loads, while stiffness refers to the material's ability to undergo elastic deformation. Generally, the wind pressure resistance performance indicators of aluminum veneer include the following aspects:

Wind resistance performance level: According to the national standard GB/T 3884-2020 "Aluminum Alloy Building Profile", the wind resistance performance of aluminum veneer is divided into 12 levels, from level 1 to level 12. The higher the level, the stronger the wind resistance ability.

Sectional area coefficient: refers to the ratio of the cross-sectional area of an aluminum veneer to the surface area of the entire aluminum veneer when subjected to wind pressure. The larger the cross-sectional area coefficient, the stronger the wind pressure resistance of aluminum veneer.

Bending stiffness: refers to the ratio of the degree of bending deformation of aluminum veneer under wind pressure to its original size. The higher the bending stiffness, the stronger the wind pressure resistance of the aluminum veneer.

1. Factors affecting the wind pressure resistance performance of aluminum veneer

The wind resistance performance of aluminum veneer is influenced by various factors, mainly including the following aspects:

Material quality: The quality of aluminum veneer is one of the important factors affecting its wind pressure resistance performance. High quality aluminum materials have higher strength and stiffness, which can better withstand external loads.

Structural design: The structural design of aluminum veneer is also one of the important factors affecting its wind pressure resistance performance. Reasonable structural design can improve the overall strength and stiffness of aluminum veneer, thereby enhancing its ability to withstand wind pressure.

Installation method: The installation method of aluminum veneer can also affect its wind pressure resistance performance. The correct installation method can ensure a firm and reliable connection between the aluminum veneer and the building, thereby improving its overall stability and safety.

1. Methods to improve the wind pressure resistance performance of aluminum veneer

In order to improve the wind pressure resistance performance of aluminum veneer, the following aspects can be taken into consideration:

Using high-quality materials: Choosing high-quality aluminum can improve the overall strength and stiffness of aluminum veneers, thereby enhancing their ability to withstand wind pressure.

Adopting appropriate structural design: Reasonable structural design can improve the overall strength and stiffness of aluminum veneer, thereby enhancing its ability to resist wind pressure. For example, structural measures such as reinforcing ribs or components can be installed on aluminum veneers.

Adopting the correct installation method: The correct installation method can ensure a firm and reliable connection between the aluminum veneer and the building, thereby improving its overall stability and safety. For example, appropriate support structures or reinforcements can be used to increase the stability of aluminum veneers.

The wind resistance performance of aluminum veneer is a very important indicator in its application. By understanding its wind resistance performance indicators, influencing factors, and improvement methods, it is possible to better select and use aluminum veneer materials, and ensure their safety and stability in strong wind environments.

Customer service QQ

Customer service QQ