Industry information

Company News

- Aluminum veneer, the fashionable outerwear of modern architecture

- Aluminum veneer: the fashionable "coat" of modern architecture

- Fluorocarbon baked paint aluminum veneer: the new favorite of aluminum materials, a new choice for quality life

- Aluminum veneer customization, creating a new trend of personalized space

- Fluorocarbon baked paint aluminum veneer: the new darling of aluminum materials and the fashion pioneer in the construction industry

Industry dynamics

- Painted aluminum veneer: a fashionable outerwear for modern architecture

- Fluorocarbon baked paint aluminum veneer: the new favorite of aluminum materials, a new choice for texture and lifestyle

- Aluminum veneer customization makes buildings more environmentally friendly and energy-efficient

- Fluorocarbon baked paint aluminum veneer: the magnificent "coat" of modern architecture

- Aluminum veneer customization, a new choice for personalized space

Frequently asked questions

- Has the production process of aluminum veneer reduced water resource consumption?

- Can aluminum veneer be customized?

- Can the insulation function of aluminum veneer reduce indoor noise?

- Is aluminum veneer prone to deformation?

- How many color and texture options are available for aluminum veneer?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Performance test report of 3mm aluminum veneer

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: March 12, 2025 21:24:28

- Click:0

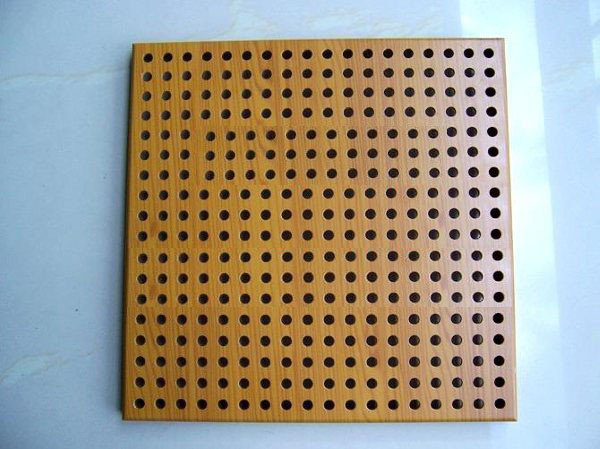

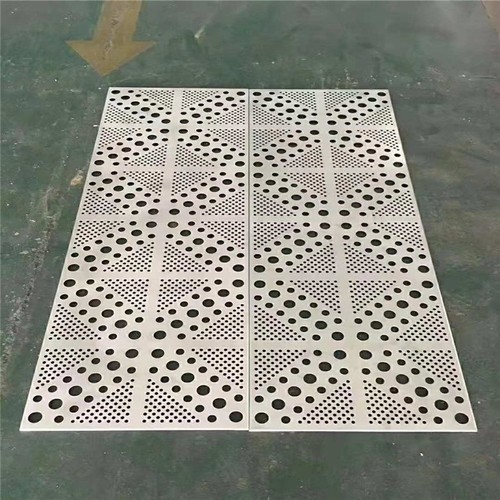

3mmAluminum veneerIt is a commonly used building material, and its performance test report is of great significance for the selection and use of this material. The performance test report of 3mm aluminum veneer will be introduced in detail from multiple aspects.

1、 Tensile strength test

Tensile strength refers to the maximum tensile force that a material can withstand during the stretching process. The tensile strength test results of 3mm aluminum veneer show that the material has a tensile strength of 50-60MPa, which can meet the load-bearing requirements of building structures.

2、 Yield strength test

Yield strength refers to the minimum stress value at which a material begins to undergo plastic deformation under external force. The yield strength test results of 3mm aluminum veneer show that the yield strength of the material is 30-40 MPa, which can alleviate the pressure on building structures to a certain extent.

3、 Hardness testing

Hardness refers to the ability of a material to resist scratches or indentations. The hardness test results of 3mm aluminum veneer show that the material has a hardness of HB180-220, with good wear resistance and scratch resistance, suitable for use in high traffic areas such as public places.

4、 Density testing

Density refers to the mass of a substance per unit volume. The density test results of 3mm aluminum veneer show that the material has a density of 2.7-3.0g/cm3, which is relatively lightweight compared to other building materials and can effectively reduce the weight of buildings.

5、 Thermal conductivity test

Thermal conductivity refers to the ratio of the amount of heat passing through a unit area per unit time to the temperature difference. The thermal conductivity test results of 3mm aluminum veneer show that the material has a thermal conductivity of 0.9-1.2W/(m · K), which has good insulation effect and can effectively reduce the energy consumption of buildings.

6、 Corrosion resistance test

Corrosion resistance refers to whether a material will undergo corrosion under the action of chemical media. The corrosion resistance test results of 3mm aluminum veneer show that the material has good corrosion resistance and can be used for a long time in acidic, alkaline and other environments.

7、 Fire performance testing

Fire resistance refers to whether a material can effectively prevent the spread of fire in the event of a fire. The fire performance test results of 3mm aluminum veneer show that the material has certain fire resistance, but necessary fire prevention measures still need to be taken to ensure the safety of the building. For example, setting up fire extinguishers or automatic sprinkler systems in public places to promptly respond to fire accidents. Regular inspections should also be conducted on the integrity and effectiveness of fire-fighting facilities to avoid fire accidents caused by aging or damage to the facilities.

Customer service QQ

Customer service QQ