Industry information

Company News

- Fluorocarbon baked paint aluminum veneer: a perfect combination of fashion and durability

- Create an exclusive style and customize aluminum veneers to make the building more charming

- How much do you know about aluminum veneer: a fashionable choice for modern architecture?

- Craftsmanship and unique baking paint aluminum veneer: a perfect fusion of fashion and durability

- Painted aluminum veneer: the new aristocrat of aluminum materials, your new favorite in decoration!

Industry dynamics

- Embark on a creative journey of aluminum veneer customization

- Application and prospects of Great Wall roll coated aluminum veneer in the field of architectural decoration

- Installation steps and precautions for indoor ceiling aluminum veneer

- Material selection and construction techniques for outdoor roller coated aluminum veneer

- What is the market supply situation of aluminum veneer?

Frequently asked questions

- Is aluminum veneer prone to deformation?

- What is the thermal conductivity of aluminum veneer?

- Can the insulation function of aluminum veneer reduce indoor noise?

- Has the production process of aluminum veneer reduced water resource consumption?

- What are the advantages and disadvantages of aluminum veneer compared to plastic exterior walls?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What is the manufacturing process of carved aluminum veneer?

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: February 20, 2025 18:31:21

- Click:0

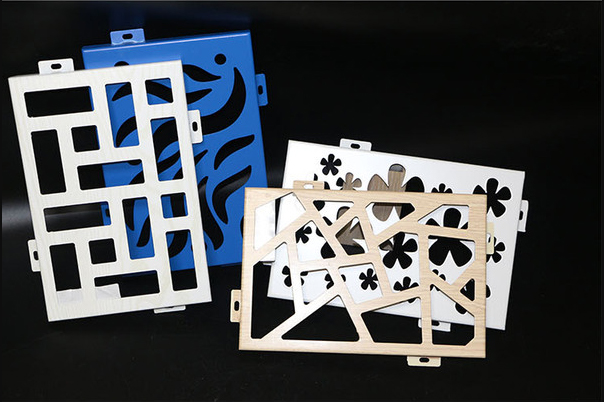

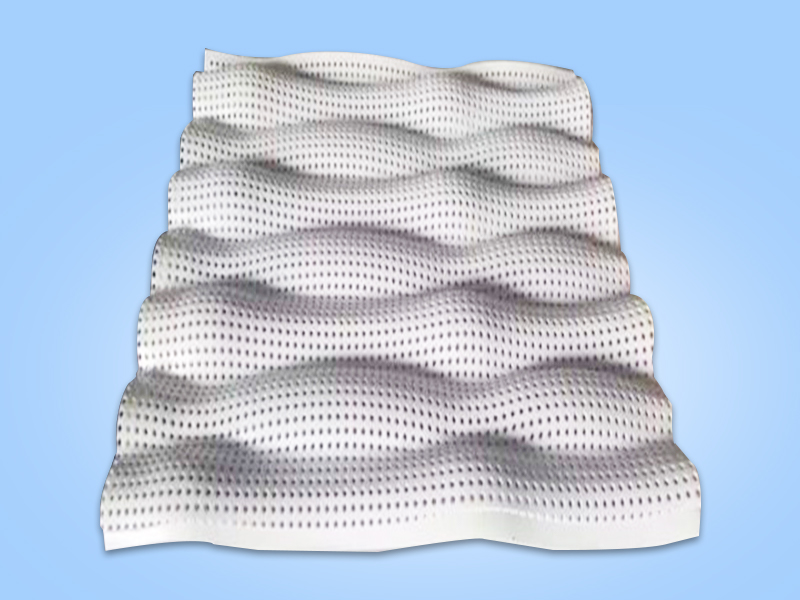

CarvingAluminum veneerIt is a very popular building material with many advantages and characteristics. The manufacturing process is one of the key factors determining its quality and performance. Below is a detailed introduction to the production process of carved aluminum veneer.

1、 Raw material preparation

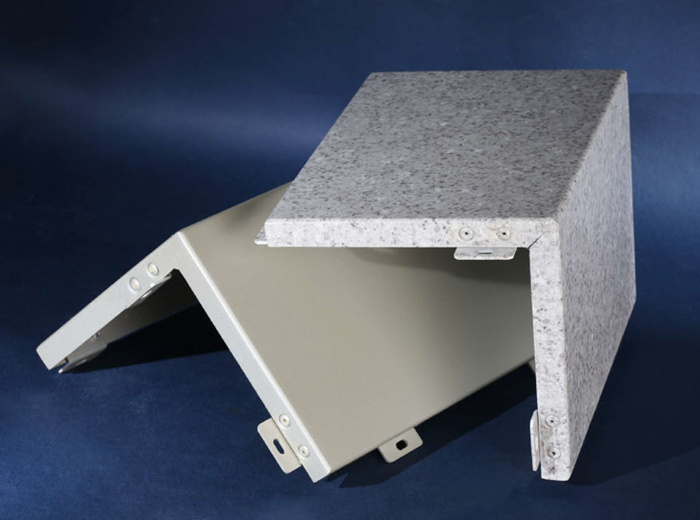

The production of carved aluminum veneer requires the use of raw materials such as aluminum alloy materials and fluorocarbon coatings. Before production, strict testing and screening of raw materials are required to ensure that they meet product quality requirements.

2、 Cutting and processing

Cutting and processing aluminum alloy materials according to design requirements can result in components of different sizes and shapes. Cutting and processing require the use of CNC machining equipment to ensure accuracy and surface smoothness.

3、 Welding processing

By welding components of different sizes and shapes, complete carved aluminum veneer products can be obtained. Welding processing requires the use of advanced welding equipment and technology to ensure the quality and strength of the weld seam.

4、 Grinding and processing

Polishing the welded carved aluminum veneer can remove burrs and defects on the surface, improving the surface smoothness and aesthetics of the product. Polishing requires the use of professional mechanical equipment and technology to ensure effectiveness and efficiency.

5、 Fluorocarbon coating treatment

Applying fluorocarbon coating to polished carved aluminum veneer can improve its weather resistance and corrosion resistance, as well as enhance its decorative effect. Fluorocarbon coating treatment requires the use of advanced coating equipment and technology to ensure the quality and uniformity of the coating.

6、 Quality inspection and testing

Conduct quality inspection on the completed carved aluminum veneer to ensure that it meets the product quality requirements. Quality inspection requires the use of professional testing equipment and techniques to ensure the accuracy and reliability of the results.

The production process of carved aluminum veneer includes raw material preparation, cutting processing, welding processing, polishing processing, fluorocarbon coating treatment, and quality inspection. Through reasonable production techniques and strict quality control, buildings can be decorated with more beautiful, practical, and environmentally friendly effects.

Customer service QQ

Customer service QQ