Industry information

Company News

- Fluorocarbon baked paint aluminum veneer, the "beauty responsibility" of the aluminum industry

- Fluorocarbon baked paint aluminum veneer: the new favorite of aluminum materials, a new trend in architecture?

- Unveiling the mysterious veil of fluorocarbon aluminum veneer

- Unveiling the Charm of Painted Aluminum Veneer with New Texture

- Fluorocarbon aluminum veneer: the new favorite of architecture, the perfect combination of fashion and durability!

Industry dynamics

- Customized aluminum veneer, creating personalized space and new fashion

- Unveiling the Fashion and Practical Charm of Aluminum Veneers in Curtain Walls

- Aluminum veneer customization, creating an artistic journey of personalized space

- Installation methods and techniques for aluminum veneer

- Revealing the installation points of aluminum veneer curtain wall

Frequently asked questions

- Can aluminum veneer be used for building facade design?

- Has the production process of aluminum veneer reduced water resource consumption?

- Can aluminum veneer be customized?

- What is the thermal conductivity of aluminum veneer?

- What are the advantages and disadvantages of aluminum veneer compared to plastic exterior walls?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What is the production process of fluorocarbon aluminum veneer?

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- 发布时间:2025-02-24 17:09:06

- Click:0

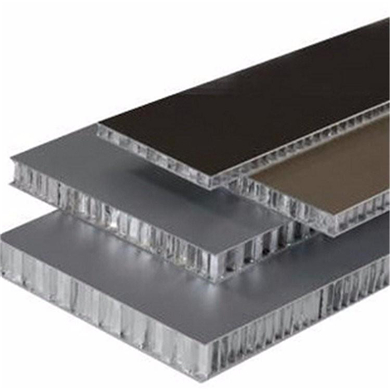

FluorocarbonAluminum veneer是一种非常流行的建筑材料,其生产工艺主要包括以下几个步骤。

一、材料准备

氟碳铝单板的生产首先需要准备好所需的原材料,包括铝合金板材、氟碳涂料、密封胶等。这些原材料需要经过严格的筛选和检测,以确保其质量符合要求。

2、 Cutting and processing

将铝合金板材按照设计要求进行切割加工,通常采用数控机床进行加工,以保证加工精度和尺寸精度。切割完成后,需要对切口进行打磨和清洗处理,以便于后续的涂装和安装。

3、 Surface treatment

将切割好的铝合金板材进行表面处理,通常是采用阳极氧化、喷涂等方式进行处理。这些处理方式可以增加铝板的耐腐蚀性和耐磨性,同时也能够提高其美观度和光泽度。

四、涂装氟碳涂料

在表面处理完成之后,需要对铝合金板材进行涂装氟碳涂料处理。涂装时需要注意涂料的质量和涂装工艺,以确保涂料能够均匀地附着在铝板上,并且具有较好的耐候性和耐腐蚀性。

五、安装固定

涂装完成后,需要对氟碳铝单板进行安装固定。这通常采用普通的螺丝和铆钉进行固定,以确保铝板的稳定性能和使用寿命。还需要使用密封胶对铝板接缝处进行密封处理,以防止雨水渗漏进入室内。

六、质量检验

在生产过程中需要对各个环节进行质量检验,以确保氟碳铝单板的质量符合要求。质量检验主要包括尺寸精度、外观质量、强度和刚度等方面的检验。如果发现质量问题,需要及时采取措施进行修正和改进。

氟碳铝单板的生产工艺主要包括材料准备、切割加工、表面处理、涂装氟碳涂料、安装固定和质量检验等几个步骤。在生产过程中需要严格控制每个环节的质量,以确保氟碳铝单板的质量符合要求。

Customer service QQ

Customer service QQ