Industry information

Company News

- Fluorocarbon baked paint aluminum veneer: the new high-end of aluminum materials, a new chapter in architectural aesthetics

- Dear architecture enthusiasts and designers, today let's talk about the one that instantly makes architecture cool

- Aluminum veneer customization, new trend of personalized space

- Aluminum veneer curtain wall: the fashionable coat of modern architecture

- Aluminum veneer curtain wall, the fashionable outerwear of modern architecture

Industry dynamics

- Aluminum veneer decoration, creating a modern and minimalist style!

- Revealing the installation points of aluminum veneer curtain wall

- What are the applications of aluminum veneer in indoor decoration?

- Maintenance skills and suggestions for aluminum veneer curtain wall

- New trend of aluminum plate: baked paint aluminum veneer, the new darling of fashionable home furnishings

Frequently asked questions

- What are the sustainability indicators of aluminum veneer in building exterior design?

- Can the insulation function of aluminum veneer reduce indoor noise?

- How many color and texture options are available for aluminum veneer?

- Has the production process of aluminum veneer reduced water resource consumption?

- Can aluminum veneer be used for building facade design?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

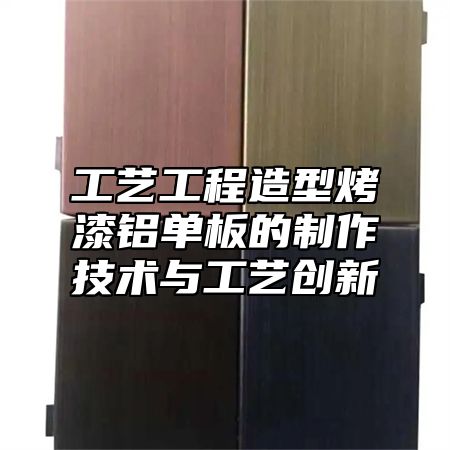

Manufacturing technology and process innovation of process engineering modeling baking paint aluminum veneer

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: February 26, 2025 23:01:30

- Click:0

With the continuous development and innovation of the architectural decoration industry, the use of styling baking paintAluminum veneerAs a new type of building material, the production technology and process innovation in process engineering are also receiving increasing attention. This article will provide a detailed introduction to the production technology and process innovation of molded baked aluminum veneer from the perspective of process engineering.

1、 Production Technology

1. Material selection

The production of molded painted aluminum veneer first requires the selection of suitable materials. High strength aluminum alloy sheets are commonly used, which can form very delicate textures and colors after special surface treatment. This material has the advantages of lightweight, high strength, and corrosion resistance, and can meet various building decoration needs.

2. Cutting and punching

During the production process, it is necessary to cut and drill holes in the aluminum alloy sheet for installation and use. Traditional cutting and drilling methods often suffer from problems such as low precision and low efficiency, while modern CNC cutting and laser drilling technologies can effectively solve these problems, improve production efficiency and product quality.

3. Surface treatment

The surface treatment of aluminum veneer with baking paint is a very important step in its production process. Through surface treatment, the surface of aluminum alloy sheets can present finer textures and colors, while also improving their waterproofing and durability. The common surface treatment methods currently include anodizing, spraying, electrophoretic coating, etc.

2、 Process innovation

1. Application of 3D printing technology

3D printing technology is an emerging manufacturing technology that can directly print designed patterns onto aluminum alloy sheets, thereby achieving more complex and refined design effects. This technology can not only improve production efficiency and product quality, but also reduce material waste and environmental pollution.

2. Application of laser engraving technology

Laser engraving technology is a high-precision and high-efficiency processing technique that can carve very detailed patterns and text on aluminum alloy sheets. This technology can not only achieve more complex design effects, but also improve the decorative and artistic quality of products.

3. Application of intelligent control system

Intelligent control system is an automation system that integrates multiple advanced technologies and can automatically adjust production processes and parameters according to different production requirements and environmental conditions. This system can greatly improve production efficiency and product quality, while also reducing the impact of human factors on the production process.

As a new type of building material, the production technology and process innovation of molded painted aluminum veneer are also receiving increasing attention in the field of process engineering. In the future development, with the continuous progress and innovation of technology, it will have a wider and more diverse range of application scenarios.

Customer service QQ

Customer service QQ