Industry information

Company News

- Fluorocarbon baked paint aluminum veneer reveals the "invisible guardian" of modern architecture

- Fluorocarbon baked paint aluminum veneer: the new favorite of aluminum materials, a new trend in architecture?

- Fluorocarbon baked paint aluminum veneer: the new favorite of aluminum materials, a new choice for quality life!

- How much do you know about aluminum veneer: a fashionable choice for modern architecture?

- Aluminum veneer customization, creating a new trend of personalized space

Industry dynamics

- What is the impact of the thickness of aluminum veneer on its performance?

- Fluorocarbon aluminum veneer: the new favorite of modern architecture, your home can also be "high-end"!

- Exploration of innovative application of twisted aluminum veneer in architectural decoration

- Aluminum veneer, the "fashionable outerwear" of the industrial industry

- Exquisite craftsmanship presents natural beauty - wood grain carved aluminum veneer

Frequently asked questions

- How many color and texture options are available for aluminum veneer?

- What is the thermal conductivity of aluminum veneer?

- Has the production process of aluminum veneer reduced water resource consumption?

- Can aluminum veneer be used for building facade design?

- Is aluminum veneer prone to deformation?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

What are the hot bending forming processes for aluminum veneer?

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: 2022-03-08 11:27:20

- Click:0

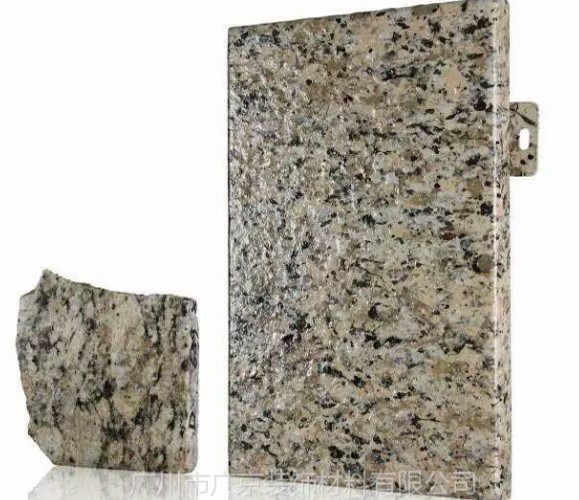

Aluminum veneerAs a commonly used building material, its hot bending process is an indispensable part of its manufacturing process. The following will provide a detailed introduction to the hot bending process and classification of aluminum veneer.

1. Introduction to Hot Bending Forming Process

The hot bending process refers to the process of heating and bending aluminum veneer to achieve the desired shape and size. This process can enable aluminum veneer to form complex curved surfaces and curves without the use of any adhesive, thus meeting the requirements of architects.

1. Classification of hot bending forming process

According to different heating and bending methods, the hot bending process of aluminum veneer can be divided into the following categories:

(1) Manual hot bending process

The manual hot bending process refers to the hot bending of aluminum veneer through manual operation. This process is suitable for the production of small aluminum veneers, but due to the need for a large amount of manpower and time, the cost is relatively high.

(2) Mechanical hot bending forming process

Mechanical hot bending process refers to the hot bending of aluminum veneer using mechanical equipment. This process is suitable for the production of large aluminum veneers, with high production efficiency and accuracy, but requires significant investment of funds and technical expertise.

(3) Electrochemical hot bending forming process

Electrochemical hot bending process refers to the hot bending of aluminum veneer through electrochemical reactions. This process is suitable for occasions that require high surface quality of aluminum veneer, such as high-end residential and commercial buildings.

(4) Laser hot bending forming process

Laser hot bending process refers to the hot bending of aluminum veneer through laser cutting and heating. This process is suitable for applications that require extremely high dimensional accuracy and surface quality of aluminum veneer, such as aerospace, medical equipment, and other fields.

Hot bending of aluminum veneer

Customer service QQ

Customer service QQ