Industry information

Company News

- Customize aluminum veneer to create personalized spatial aesthetics

- Fluorocarbon aluminum veneer: the "fashionable coat" of modern architecture

- Painted aluminum veneer: the "fashionista" of the aluminum industry

- Dear decoration novices and tasteful decoration experts, today let's talk about a topic in the decoration industry

- Fluorocarbon baked paint aluminum veneer: a texture revolution of the weather resistant king

Industry dynamics

- What is the antioxidant performance of curtain wall aluminum veneer?

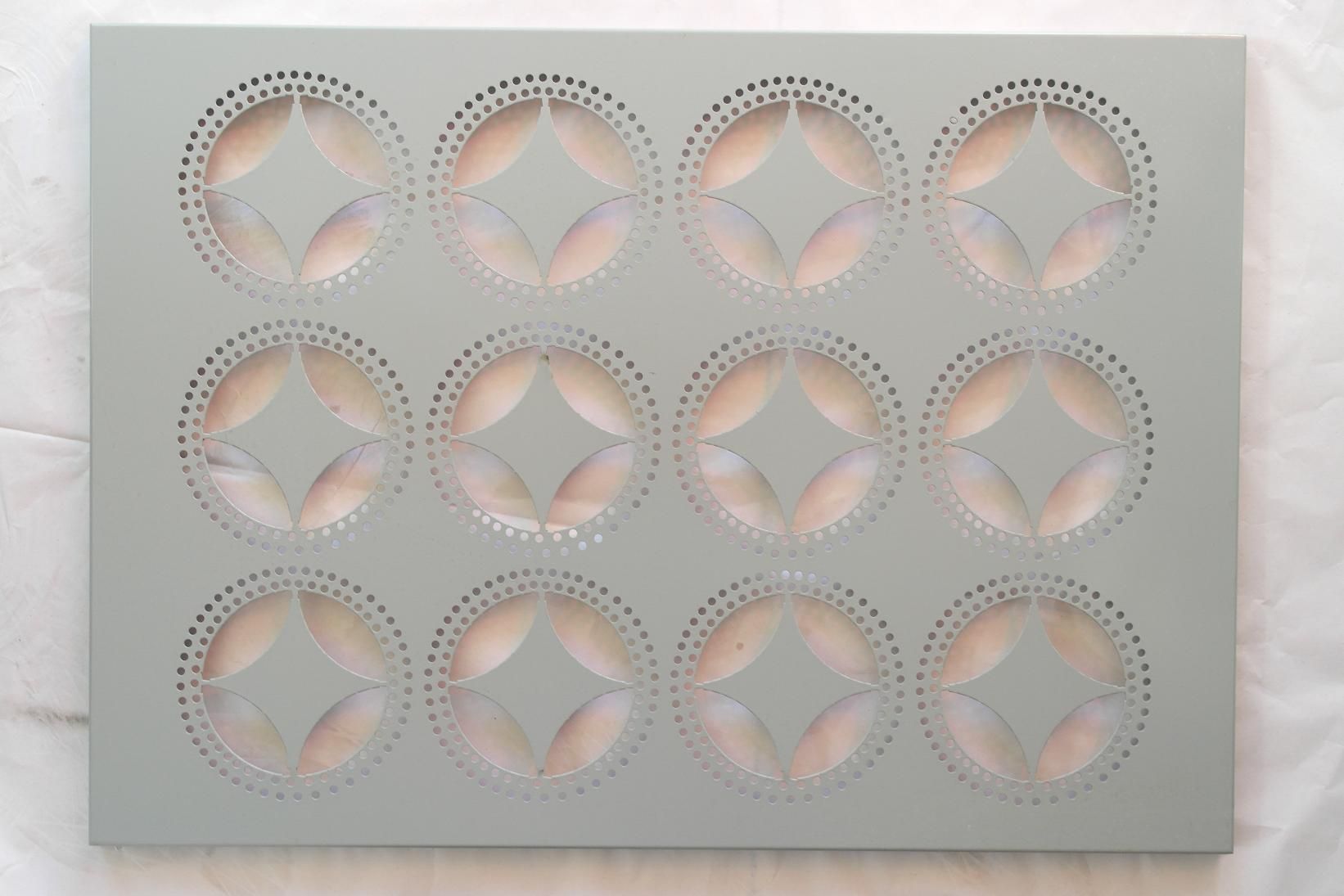

- Exhibition of Fine Cutting and Processing Techniques for 2mm Aluminum Veneer

- Fluorocarbon aluminum veneer: the "fashionable coat" of modern architecture

- Customized aluminum veneer creates exclusive space, combining art and practicality

- Design of environmentally friendly and energy-saving exterior aluminum panel curtain wall system

Frequently asked questions

- What are the sustainability indicators of aluminum veneer in building exterior design?

- Has the production process of aluminum veneer reduced water resource consumption?

- What are the advantages and disadvantages of aluminum veneer compared to plastic exterior walls?

- Can the insulation function of aluminum veneer reduce indoor noise?

- Is aluminum veneer prone to deformation?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

The production process and equipment maintenance of aluminum veneer: measures to improve production efficiency

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: March 7, 2025 15:03:12

- Click:0

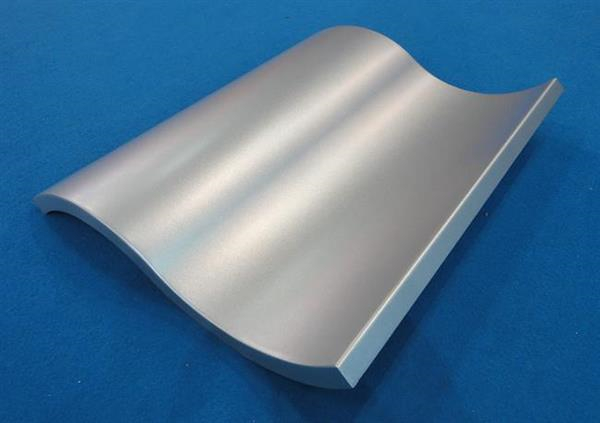

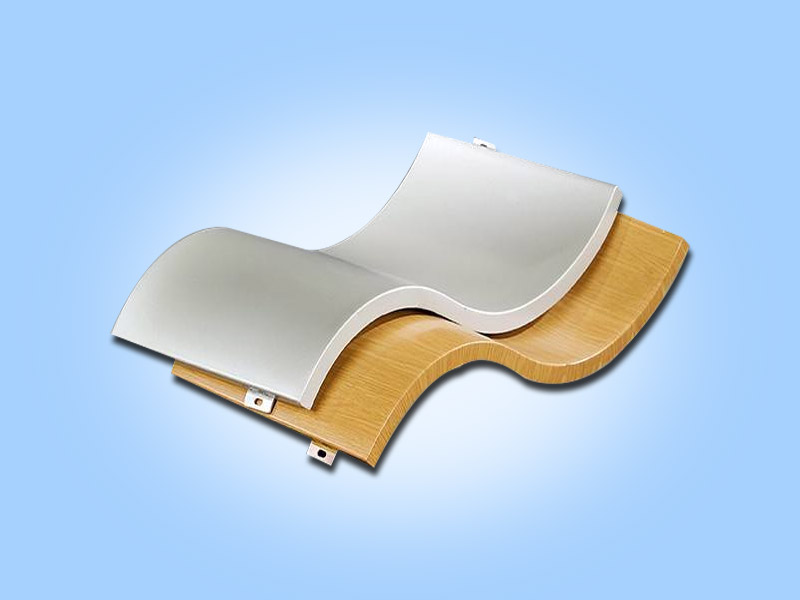

Aluminum veneerAs a new type of building material, it has the advantages of lightweight, high strength, corrosion resistance, sound insulation, etc., and is highly favored in the construction industry. The production efficiency and equipment maintenance of aluminum veneer are still two important issues facing enterprises. Below, we will provide a detailed introduction to the production process and equipment maintenance of aluminum veneer, as well as measures to improve production efficiency.

The production process of aluminum veneer needs to be continuously optimized and improved. At present, the production process of aluminum veneer mainly includes raw material procurement, cutting, drilling, spraying and other links. In order to improve production efficiency and reduce costs, enterprises can achieve this by optimizing their production process flow. For example, some enterprises adopt fully automated production lines, which can achieve rapid production and precise processing of aluminum veneer; Some enterprises adopt advanced surface treatment technologies such as spraying and rolling, which can achieve efficient production and high-quality products.

The maintenance of aluminum veneer equipment is also an important measure to improve production efficiency. Various mechanical equipment such as cutting machines, drilling machines, spraying machines, etc. are required in the production process of aluminum veneer. The normal operation of these devices has a crucial impact on the production efficiency and product quality of enterprises. Enterprises need to strengthen the maintenance and management of equipment, timely detect and solve equipment failures, and ensure the normal operation and service life of equipment. Enterprises also need to regularly maintain and repair equipment to ensure its performance and quality.

Thirdly, aluminum veneer production enterprises can also improve production efficiency by strengthening personnel training and technical exchanges. For example, some companies regularly organize employees to participate in technical training and skill enhancement courses to improve their technical skills and operational abilities; Some companies will also engage in technical exchanges and cooperation with other aluminum veneer production enterprises to jointly explore methods and approaches for improving production technology and processes.

The production process and equipment maintenance of aluminum veneer are important measures to improve production efficiency. Only by continuously optimizing and improving production processes and equipment maintenance management can enterprises enhance their competitiveness and market share. Both investors and production enterprises need to closely monitor the new technologies and trends in the aluminum veneer industry, adjust their business strategies and investment directions in a timely manner, in order to seize market opportunities.

Customer service QQ

Customer service QQ