Industry information

Company News

- Painted aluminum veneer: the fashionable choice for modern architecture?

- Painted aluminum veneer, the fashionable "coat" of modern architecture

- The aesthetic journey of aluminum veneer curtain wall separated by a board

- Aluminum veneer customization, creating a new trend of personalized space

- Fluorocarbon aluminum veneer: a modern interpretation of architectural aesthetics

Industry dynamics

- Fluorocarbon baked paint aluminum veneer: the "beauty responsibility" of the aluminum industry

- Aluminum veneer: the new darling of industrial aesthetics, creating a unique spatial style

- Curtain Wall Aluminum Veneer: The Beauty of Modern Architecture, Revealing the Story Behind It

- Market analysis and prediction of aluminum veneer price trend

- Fluorocarbon aluminum veneer: not just aluminum, it is the fashionable new favorite of architecture

Frequently asked questions

- Has the production process of aluminum veneer reduced water resource consumption?

- How many color and texture options are available for aluminum veneer?

- Is aluminum veneer prone to deformation?

- What are the sustainability indicators of aluminum veneer in building exterior design?

- Can the insulation function of aluminum veneer reduce indoor noise?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

6 processes for aluminum veneer design and manufacturing

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: 2022-03-20 16:50:17

- Click:0

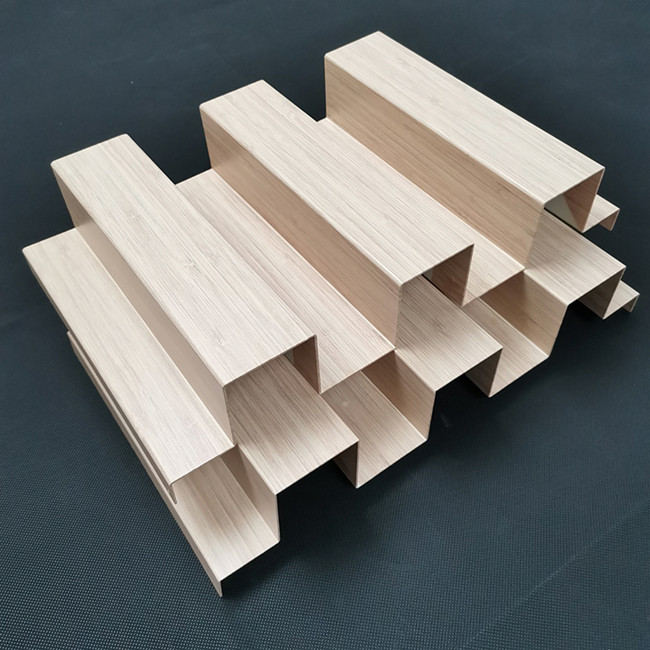

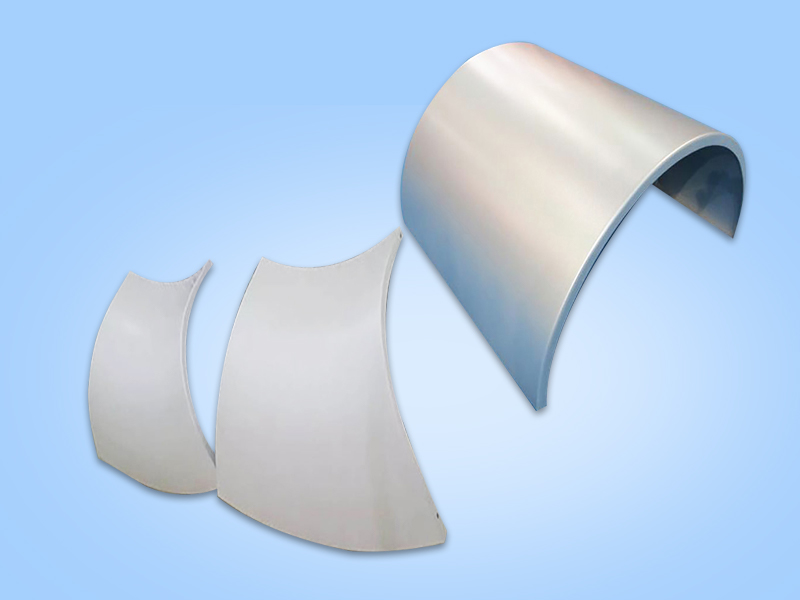

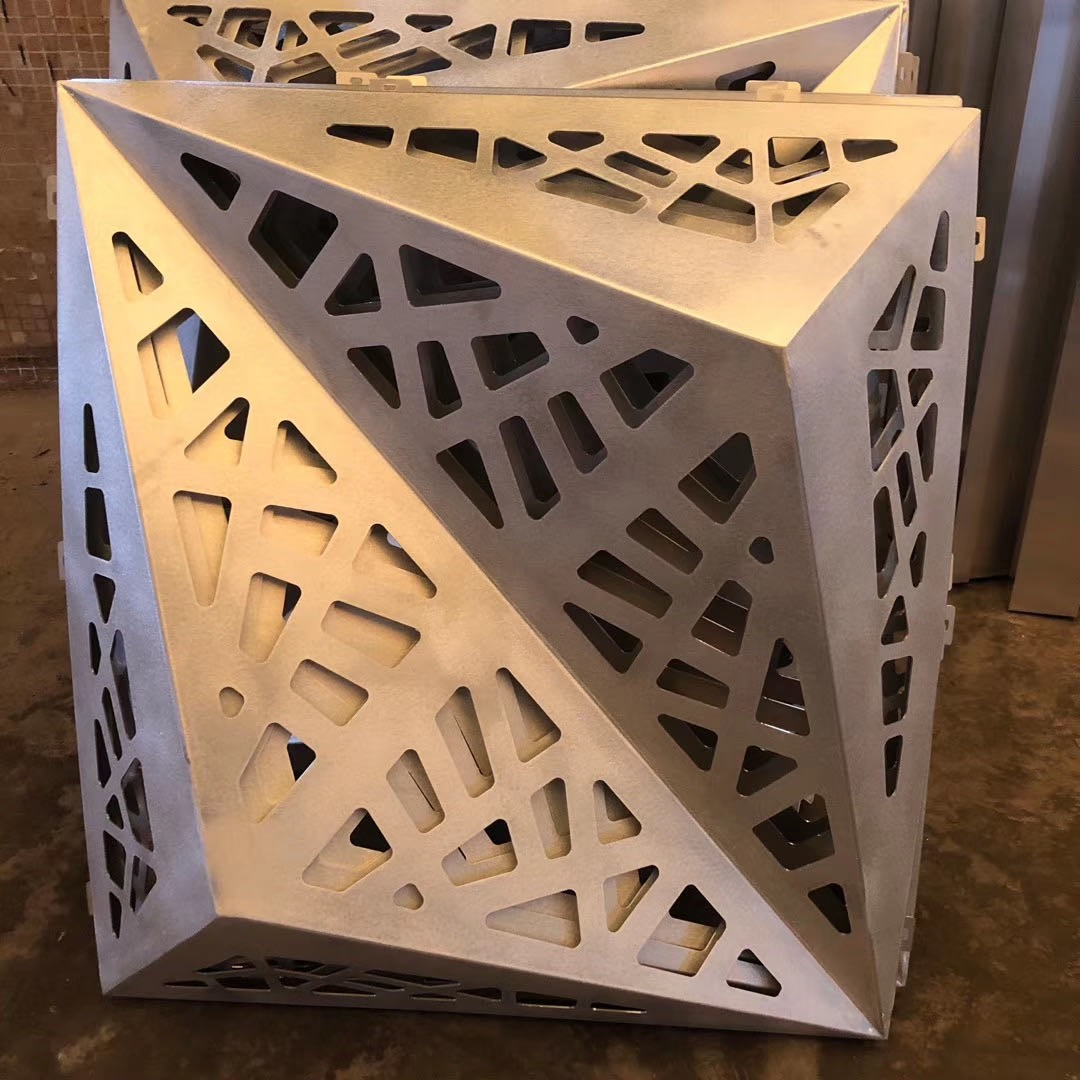

Aluminum veneerAs a new type of building material, it has the advantages of lightweight, high strength, and strong decorative properties. The design and manufacturing of aluminum veneer are also key factors in ensuring its quality and effectiveness. Below, we will introduce six processes related to the design and manufacturing of aluminum veneer.

1. Design process: The design of aluminum veneer is an important link in ensuring its quality and effectiveness. In the design process, it is necessary to consider the requirements of the size, shape, color, surface treatment, and other aspects of the aluminum veneer, and make necessary modifications and adjustments according to the actual situation. It is also necessary to consider the usage environment and requirements of aluminum veneer to ensure that it meets actual needs.

2. Raw material procurement process: The procurement of raw materials for aluminum veneer is the foundation for ensuring its quality and effectiveness. In the process of raw material procurement, it is necessary to select raw material suppliers that meet national and industry standards, and conduct strict quality testing and certification on them. It is also necessary to classify and store raw materials to ensure their quality and safety.

3. Cutting process: Cutting aluminum veneer is one of the key processes to ensure its dimensional accuracy and surface flatness. During the cutting process, professional equipment and technology are required to ensure the accuracy and efficiency of the cutting. Attention should also be paid to the safety and environmental issues of cutting to avoid causing personal injury and environmental pollution.

4. Welding process: Welding of aluminum veneer is one of the key processes to ensure its structural stability and connection strength. During the welding process, professional equipment and techniques are required to ensure the quality and efficiency of the welding. Attention should also be paid to welding safety and environmental protection issues to avoid causing personal injury and environmental pollution.

5. Surface treatment process: Surface treatment of aluminum veneer is one of the key processes to ensure its aesthetics and anti-corrosion performance. During the surface treatment process, professional equipment and techniques are required to ensure the quality and efficiency of the surface treatment. Attention should also be paid to the safety and environmental issues of surface treatment to avoid causing personal injury and environmental pollution.

6. Packaging and transportation process: The packaging and transportation of aluminum veneer is one of the key processes to ensure its quality and safety. During the packaging and transportation process, it is necessary to select packaging materials and transportation vehicles that meet national and industry standards, and conduct strict quality testing and certification. Attention should also be paid to the safety and environmental protection of packaging and transportation to avoid causing personal injury and environmental pollution.

The above six processes related to the design and manufacturing of aluminum veneer are key links in ensuring the quality and effectiveness of aluminum veneer. Consumers should choose products that meet these process requirements when choosing aluminum veneer, and request relevant testing reports and certificates. It is recommended that consumers pay attention to reasonable use and maintenance when using aluminum veneer to extend its service life and maintain good quality and effectiveness.

Customer service QQ

Customer service QQ