Industry information

Company News

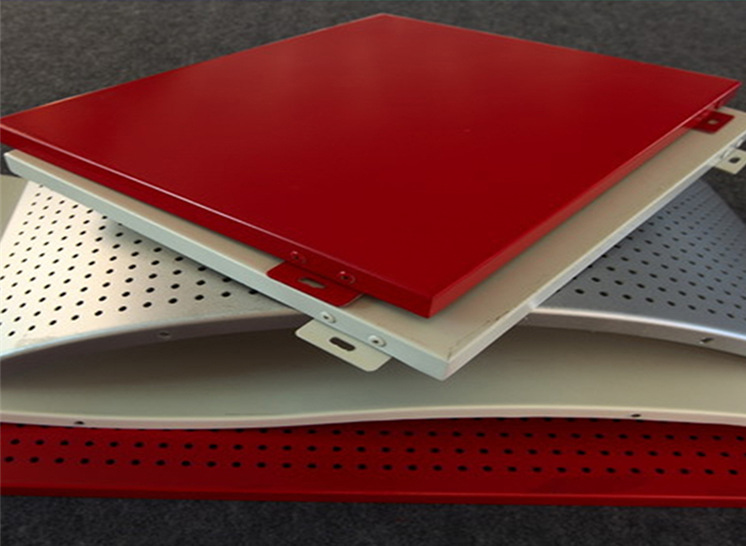

- Aluminum veneer customization, creating exclusive space aesthetics

- Painted aluminum veneer: a color magician in modern architecture

- Fluorocarbon baked paint aluminum veneer: the new favorite of aluminum materials, the perfect combination of fashion and durability

- Aluminum veneer, the 'invisible star' in modern architecture

- Aluminum veneer customization, creating a new choice for personalized space!

Industry dynamics

- Wood grain aluminum square curtain wall enhances the architectural grade and shapes the quality image.

- New building material fluorocarbon aluminum veneer

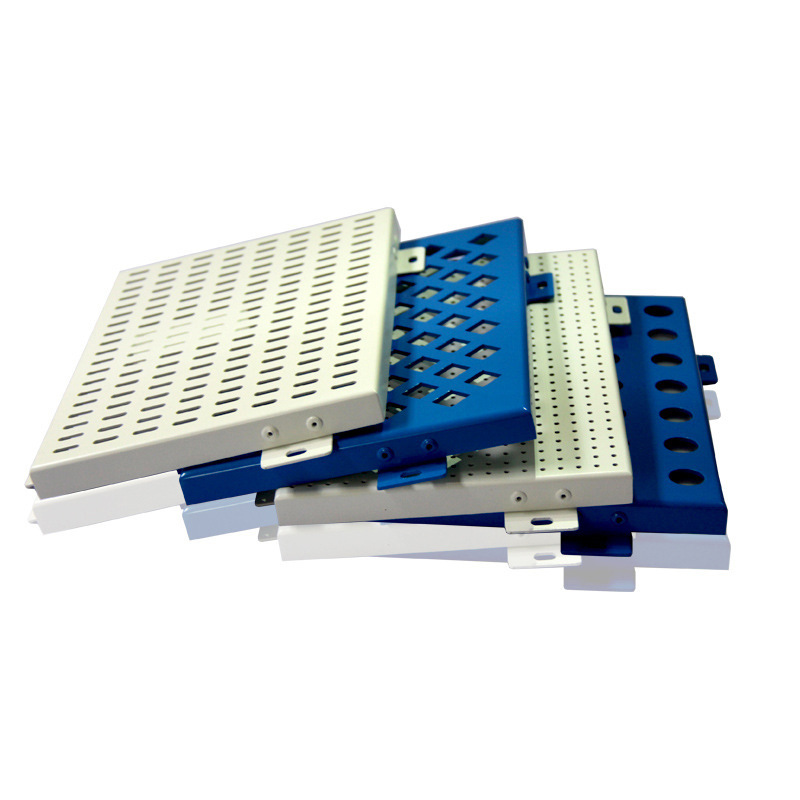

- Comfortable space ceiling hollow aluminum veneer enhances indoor comfort

- Personalized custom art hollow aluminum veneer meets your architectural creativity

- Aluminum veneer: not just sheet metal, it is the fashionable language of architecture

Frequently asked questions

- Is aluminum veneer prone to deformation?

- What is the thermal conductivity of aluminum veneer?

- What are the advantages and disadvantages of aluminum veneer compared to plastic exterior walls?

- Has the production process of aluminum veneer reduced water resource consumption?

- What are the sustainability indicators of aluminum veneer in building exterior design?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Introduction to Wood Grain 2.0mm Aluminum Veneer Process

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: February 24, 2025 19:57:17

- Click:0

Wood grain 2.0mmAluminum veneerIt is a new type of building material that presents a wood like texture on its surface, with advantages such as beauty, environmental friendliness, and durability. In terms of production technology, the wood grain 2.0mm aluminum veneer also has a unique manufacturing process. Next, let's provide a detailed introduction to the process of wood grain 2.0mm aluminum veneer.

1、 Raw material preparation

1. Aluminum alloy sheet

The main raw material for wood grain 2.0mm aluminum veneer is aluminum alloy sheet, with a thickness generally around 2.0mm. In order to ensure the quality and performance of aluminum veneer, it is necessary to choose high-quality aluminum alloy sheets as raw materials.

1. Wood grain film

The surface effect of wood grain 2.0mm aluminum veneer is achieved through wood grain film. We need to choose wood grain film with good adhesion and wear resistance as the raw material.

2、 Cutting and processing

1. Cutting materials

Cut and process aluminum alloy sheets according to design requirements to obtain aluminum veneers of the required size and shape.

1. Bending

Bend the aluminum veneer for subsequent installation and use.

3、 Surface treatment

1. Cleaning

Clean the aluminum veneer to remove surface dirt and oil stains.

1. Chromic acid anodizing treatment

Perform chromic acid anodizing treatment on aluminum veneer to form a layer of oxide film on its surface. This oxide film can improve the wear resistance and corrosion resistance of aluminum veneer, while also increasing its surface aesthetics.

4、 Printing wood grain film

1. Preparation of printing equipment

Prepare the equipment and materials required for printing wood grain film.

1. Print wood grain film onto aluminum veneer

Print the printed wood grain film onto the aluminum veneer to create a wood like texture on its surface. This step requires precise control of the printing quality and position to ensure that the final decorative effect meets the design requirements.

5、 Spray primer

Customer service QQ

Customer service QQ