Industry information

Company News

- Aluminum veneer curtain wall: the "fashionable coat" of modern architecture

- Painted aluminum veneer: a fashionable choice for modern architecture

- Curtain wall aluminum veneer: a fashionable outerwear for modern architecture

- Aluminum veneer curtain wall, the new darling of architectural aesthetics!

- Curtain wall aluminum veneer, creating a new style of modern architecture!

Industry dynamics

- Fluorocarbon aluminum veneer: the secret weapon for creating fashionable buildings!

- Is the strength of aluminum veneer related to its thickness?

- Aluminum veneer: a low-key luxury choice in modern architecture

- Aluminum veneer provides a variety of shapes and colors for buildings to choose from

- Introduction to Wood Grain 2.0mm Aluminum Veneer Process

Frequently asked questions

- Has the production process of aluminum veneer reduced water resource consumption?

- How to evaluate the impact of aluminum veneer's removability on the appearance of buildings?

- What is the thermal conductivity of aluminum veneer?

- Can aluminum veneer be used for building facade design?

- What are the sustainability indicators of aluminum veneer in building exterior design?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Surface treatment technology for 2.5mm aluminum veneer

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: March 10, 2025 09:50:55

- Click:0

Aluminum veneerIt is a lightweight, weather resistant, fire-resistant, and corrosion-resistant building material that has a wide range of applications in architectural decoration. 2.5mm thick aluminum veneer is a common specification with high strength and stability, suitable for various building applications. This article will provide a detailed introduction from multiple aspects to address the surface treatment technology issues of 2.5mm aluminum veneer.

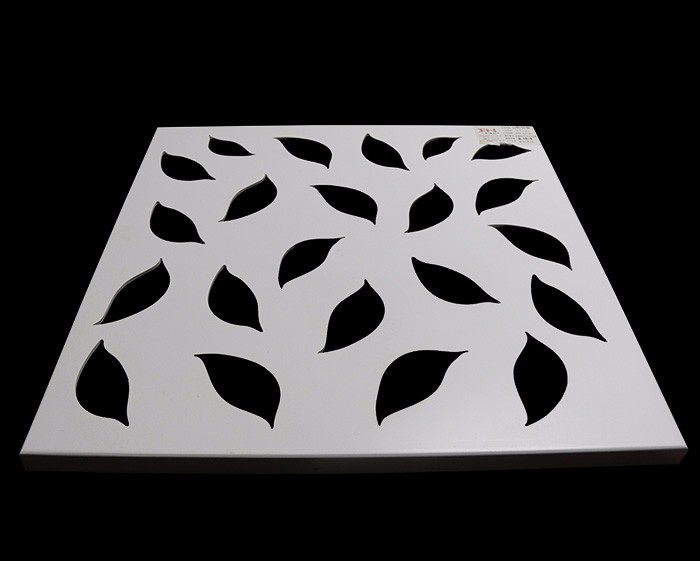

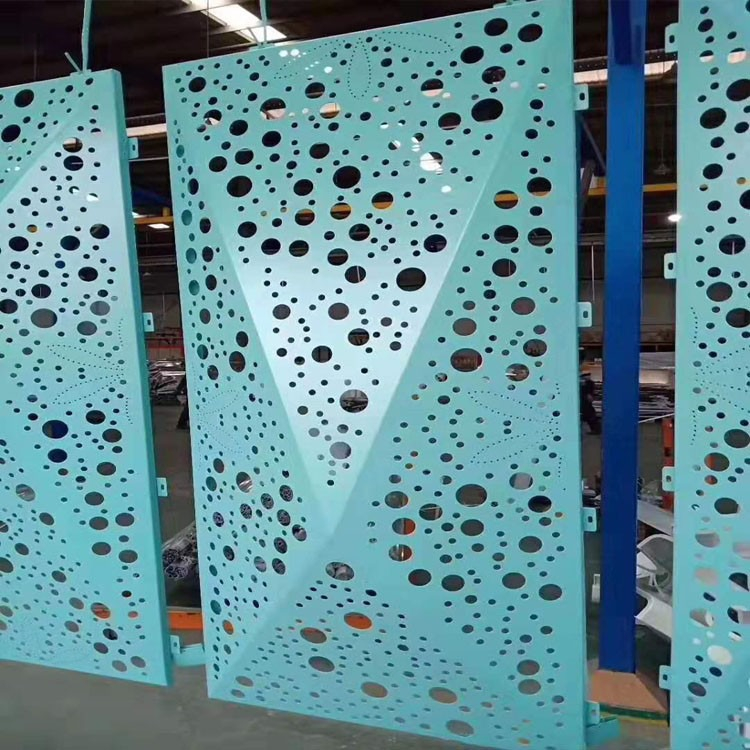

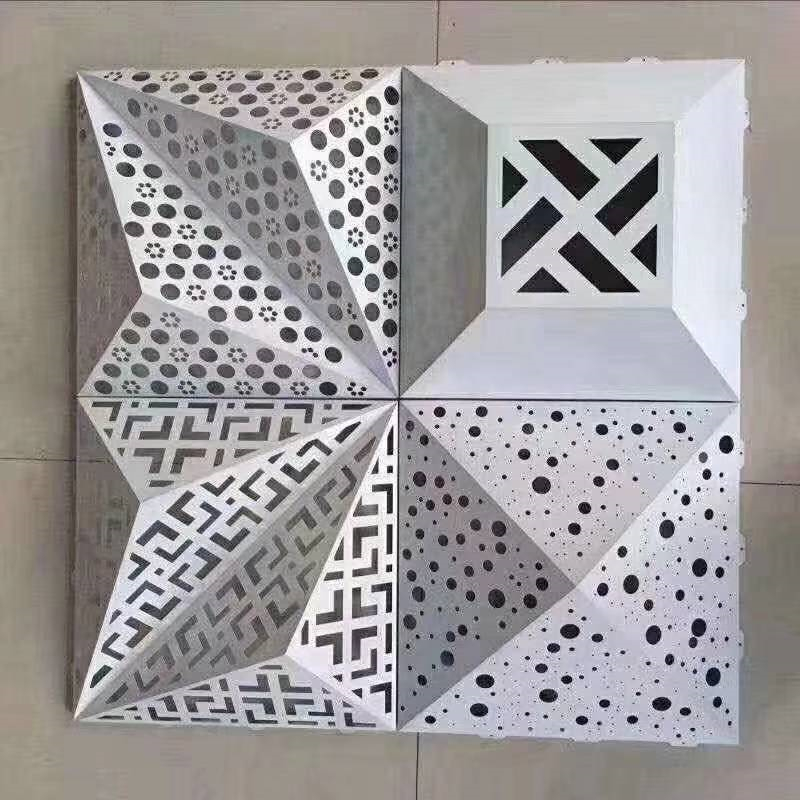

The surface treatment techniques for 2.5mm thick aluminum veneer mainly include spraying, anodizing, and electrophoretic coating. Spraying is the most common surface treatment method, which can make aluminum veneer present different colors and textures, such as white, gray, gold, silver, etc; At the same time, it can also improve the corrosion resistance and wear resistance of aluminum veneer. Anodizing is another commonly used surface treatment method, which can form a hard oxide film on the surface of aluminum veneer, thereby improving its wear resistance and corrosion resistance. Electrophoretic coating is an advanced surface treatment method that can form a uniform and dense coating on the surface of aluminum veneer, thereby improving its waterproof and anti-corrosion properties.

The surface treatment technology for 2.5mm thick aluminum veneer also needs to consider the quality and performance of the material. The surface treatment techniques used for aluminum veneers of different brands and models may vary, so it is necessary to choose the appropriate materials and treatment methods according to the actual situation. It is also necessary to consider factors such as material cost and availability to ensure the smooth acquisition of aluminum veneer with the required surface treatment effect.

Thirdly, the surface treatment technology of 2.5mm thick aluminum veneer needs to comply with relevant laws, regulations, and industry standards. For example, in some countries and regions, there may be restrictions or prohibitions on the use of certain surface treatment methods, so it is necessary to choose according to local regulations and standards. Attention should also be paid to the requirements of protecting the environment and human health, and avoiding the use of surface treatment methods that are harmful to the environment and human health.

It should be noted that the surface treatment technology of 2.5mm thick aluminum veneer needs to be operated by professionals. Due to the light weight and high strength of aluminum veneer, it requires certain surface treatment experience and technical capabilities to complete the surface treatment work. If there is no relevant experience, it is recommended to hire a professional construction team for surface treatment.

The surface treatment technology of 2.5mm thick aluminum veneer is a process that requires comprehensive consideration of multiple factors. By selecting appropriate surface treatment methods, considering the quality and performance of materials, following relevant laws and regulations and industry standards, and being operated by professionals, the surface treatment quality and effect of aluminum veneer can be guaranteed. When designing building decoration materials, it is necessary to choose suitable materials and design schemes according to specific situations to ensure the quality and stability of the overall decoration effect.

Customer service QQ

Customer service QQ