Industry information

Company News

- Fluorocarbon aluminum veneer: the "invisible armor" of modern architecture

- Fluorocarbon baked paint aluminum veneer: the new darling of modern architecture?

- Painted aluminum veneer: the "fashionista" of the aluminum industry

- Aluminum veneer: the dazzling silver style in modern architecture

- Aluminum veneer customization, creating a new trend of personalized space

Industry dynamics

- Artistic wall aluminum veneer decoration rendering

- How to improve the production efficiency of aluminum veneer?

- Customized installation process and technology for aluminum veneer

- Introduction to Wood Grain 2.0mm Aluminum Veneer Process

- Fluorocarbon baked paint aluminum veneer: the new darling of the aluminum industry, a beautiful secret!

Frequently asked questions

- What are the advantages and disadvantages of aluminum veneer compared to plastic exterior walls?

- Is aluminum veneer prone to deformation?

- How many color and texture options are available for aluminum veneer?

- Has the production process of aluminum veneer reduced water resource consumption?

- How to evaluate the impact of aluminum veneer's removability on the appearance of buildings?

contact us

Mobile:+86 15627778610

Email: 2201229786

Address: No. 5 Binjiang Road, High tech Zone, Zhaoqing City, Guangdong Province

Cutting and processing technology of imitation wood grain aluminum veneer

- Author: Supreme Building Materials (Guangdong) Co., Ltd

- Release time: February 22, 2025 at 02:58:40

- Click:0

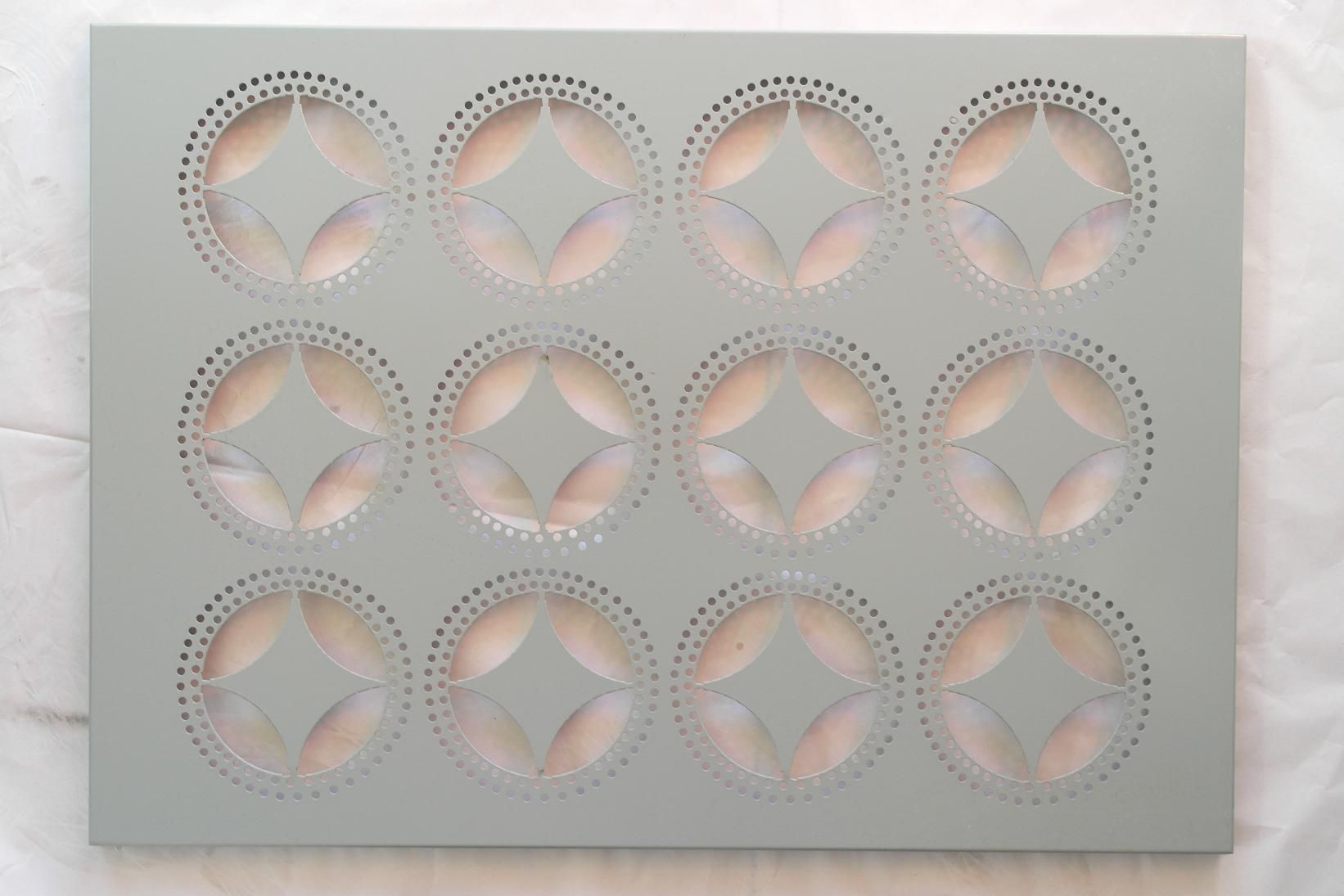

GrainingAluminum veneerAs a building material, its cutting and processing technology has a significant impact on its appearance and performance. Below is a detailed introduction to the cutting and processing technology of imitation wood grain aluminum veneer.

1、 Cutting equipment

1. CNC cutting machine: CNC cutting machine is currently the most commonly used cutting equipment for imitation wood grain aluminum veneer. It has the advantages of high precision, high efficiency, and low energy consumption, and can meet the cutting requirements of various complex shapes.

2. Manual cutting tools: Manual cutting tools include hand saws, hand planes, etc., suitable for cutting some simple shapes and sizes of imitation wood grain aluminum veneer.

2、 Cutting process

1. Design drawings: Before cutting the imitation wood grain aluminum veneer, it is necessary to accurately measure and calculate according to the design drawings to determine the size and shape of each part.

2. Material preparation: Before cutting, it is necessary to inspect and clean the raw materials to ensure that their surfaces have no obvious defects or flaws.

3. Cutting sequence: Generally speaking, the cutting sequence of imitation wood grain aluminum veneer should be from large to small, from coarse to fine, and from outside to inside. This can ensure the quality and accuracy of cutting.

4. Safety measures: When cutting, attention should be paid to safety issues to avoid accidental injuries. Fire and explosion prevention measures need to be taken to ensure the safety and reliability of the production process.

3、 Precautions

Before cutting, it is necessary to carefully inspect and maintain the cutting equipment to ensure its normal operation and safety.

When cutting, it is necessary to choose the appropriate tool and cutting speed according to the actual situation to avoid problems such as overheating and excessive wear.

3. When cutting, attention should be paid to factors such as material hardness and strength to avoid cutting failure or material damage caused by material problems.

4、 Conclusion

The cutting and processing technology of imitation wood grain aluminum veneer is one of the important factors to ensure the appearance and performance of the product. In the future development, with the advancement of technology and changes in market demand, the cutting and processing technology of imitation wood grain aluminum veneer will continue to innovate and improve, creating a better and more comfortable living environment and social atmosphere for people.

Customer service QQ

Customer service QQ